Introduction

When customers lease a cage, they’re often thinking about “space and power.” But an important second layer of detail is how that space is organized internally — i.e. how many racks or cabinets, what types, how dense, how to route power and fiber, how to provide access and support. A well-designed internal layout can dramatically improve operational efficiency, cooling effectiveness, cable management, and customer satisfaction.

In this article, we’ll cover:

- Types of rack / cabinet / enclosure options inside cages (4-post racks, full cabinets, half cabinets, modular divisions)

- Design trade-offs (density, cooling, access, serviceability)

- How we (as the operator) can provide value-add services: mounting PDUs, running fiber, installing ladder trays, overhead cable bridges

- Sample layouts and best practices

- How to present these options to customers (flexible configuration templates)

Let’s begin by defining the main variants of rack / cabinet types and how they fit inside cages.

Rack / Cabinet / Enclosure Options inside a Cage

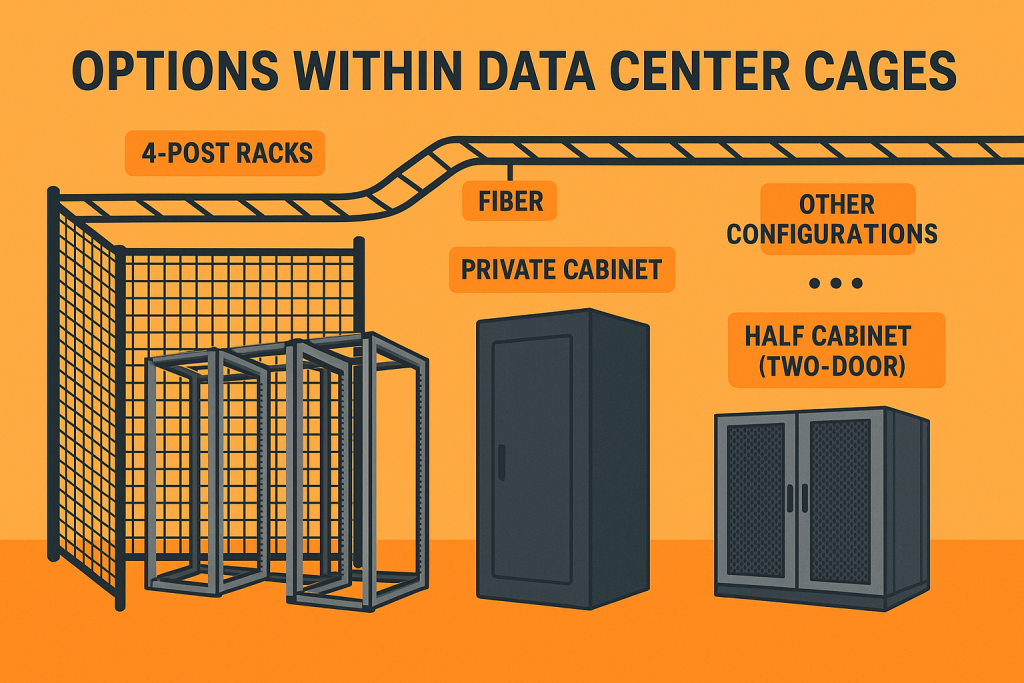

Within a customer’s cage (a mesh-wall enclosure or partitioned area), you as the provider can allow (or supply) a range of rack or cabinet types. Common options include:

- Open 4-Post Racks (No Enclosure)

- Enclosed Cabinets / Private Cabinets (Full Height)

- Half-Height or Half-Width Cabinets / Two-Door Cabinets

- Compartments / Multi-tenant compartments inside a cabinet (multi-compartment)

- Custom modular or cluster configurations

Below is a detailed discussion of each.

1. Open 4-Post Racks (No Enclosure)

Description & Use Case

Open 4-post racks are simple frames with four vertical posts (two front, two rear), with rails between them for equipment mounting. They may or may not include side covers or doors; often, in a cage environment, one uses open racks to maximize airflow and minimize enclosure overhead. These are sometimes referred to simply as “racks” (versus “cabinets”).

Advantages

- Excellent airflow — no doors or panels to block cooling

- Easier access and maintenance from front/back/sides

- Lower cost (no enclosure panels, doors, locks)

- Flexibility of arrangement — you can group racks, leave space, etc.

Considerations / Trade-offs

- Less security (you rely on cage walls, not rack doors)

- Potential for more cable exposure and mess unless cable management is strong

- Needs good containment planning (cold/hot aisle) to avoid recirculation

- May require more floor space clearance at ends

Design Notes

- Use high-quality 4-post frames rated for the expected weight

- Use adjustable mounting rails (front/rear) to account for variable depths

- Provide vertical/horizontal cable management channels attached to the rack

- Consider zero-U cable organizers or vertical managers

- Provide pathways for PDUs and power, either behind racks or alongside

Open 4-post racks are common in dense cage deployments where customers wish to bring their own equipment and prioritize cooling and flexibility.

2. Enclosed Private Cabinets (Full Height)

Description & Use Case

A private cabinet is an enclosed rack — with front and rear doors, side panels, and sometimes top covers. This gives more security, dust control, and structured cabling, but with a “cabinet” form factor rather than bare rack. In a cage context, customers inside the cage may want cabinets to segregate their own racks further inside their cage space.

Advantages

- Lockable doors and enhanced security

- Better dust, debris, or incidental protection

- Easier to manage cable routing inside a closed shell

- Aesthetic and more “finished” appearance

- Side panels may help in thermal separation, reduce cross-flow

Considerations / Trade-offs

- Doors, panels, and locks add cost

- Doors can restrict airflow if not adequately vented

- Servicing the back often requires door swing space

- Need design for top/bottom cable entry

- May require more cooling planning due to panel resistance

Design Notes

- Use perforated front and rear doors to maintain airflow

- Side panels often removable (quick-release) to allow service access

- Top or bottom (or both) cable entry panels (knockouts)

- Grounding lugs and bonding across cabinet structure

- Use recessed PDU cavities (some cabinets include built-in PDU mounting channels) (Nucor Data Systems)

- Use mid-mounting rails or adjustable rails to accommodate different equipment depths

Many colocation providers (e.g. Equinix) offer “Secure Cabinets” as standard building blocks within cages or even stand-alone, with 45 RU, deep depth, and preconfigured power circuits. (US English)

3. Half-Height or Half-Width Cabinets / Two-Door Cabinets

Description & Use Case

These are more modular, fractional cabinet units — e.g. a “half cabinet” (meaning a cabinet that occupies only half the cage footprint or half the vertical height), or cabinets with dual doors (two-door design) which may mean two access doors (front and rear) or two compartments. Sometimes, in large cabinets, you partition them internally to create two customer compartments, each with its own door. This is sometimes referred to as “multi-compartment cabinets.” (Nucor Data Systems)

Advantages

- More efficient use of cage space — a customer without full-cabinet demand can pay for half the footprint

- Shared mechanical shell but separate compartments lend internal modularity

- Flexibility to upsell: customer can add the other half later

- Enables densification — two halves may share cooling, but have separate power/management

Considerations / Trade-offs

- Internal partitioning complicates cable/power routing

- Ensure adequate segregation of power and cooling

- Noise or thermal interaction across compartments

- Doors may interfere if two doors swing into each other

Design Notes

- Use internal metal divider panels within the cabinet

- Provide separate PDU access per compartment

- Ensure that cable pass-throughs do not compromise the security of both partitions

- In dual-door designs, ensure door clearances do not block adjacent access

- For “half-height” cabinets, height might be 24–25 RU (vs full 42–48 RU)

- In cabinets designed for high density, some manufacturers provide convertible multi-compartment designs that can be reconfigured in the field (Nucor Data Systems)

4. Compartments / Multi-Compartment Cabinet Designs

Some cabinet vendors offer flexible compartments within a single cabinet — e.g. a single shell that can be split into 2, 4, or 8 independent compartments, each with separate locks, pathways, and cable/power routing. (Nucor Data Systems) These are ideal when you expect customers may want to scale or partition later, or share a shell footprint but segregate responsibility.

This approach allows in-cage flexibility: the cage shell might contain, say, a 2-compartment cabinet plus a bare 4-post rack, enabling multiple density zones inside a single cage.

5. Custom / Modular Clusters (Hybrid Configurations)

You might also support hybrid clusters: a row of open racks mixed with cabinets and compartmental units. For example:

- At the front edge of a cage, use open 4-post racks for networking or patch gear

- Mid-row: private cabinets for compute

- Back row: half cabinets or modular compartments for growth

- Interspersed: cable trays, fiber breakouts, PDU banks

The key is you as the operator provision the infrastructure (floor loading, cooling, overhead trays, ladders) and the cage “shell,” and let customers pick a combination of rack/cabinet options best matching their use case.

Value-Add Infrastructure: PDUs, Fiber, Ladder & Overhead Bridge, Cable Routing

A major differentiator is how much you, the facility operator, provide inside the cage. Customers expect not just “empty floor and power,” but value-add infrastructure. Below are key services you can provide:

Power Distribution Units (PDUs)

What They Are

PDUs are devices that take a larger power feed (single-phase or three-phase) and distribute it as multiple lower-voltage outlets suitable for servers, networking gear, etc. Some PDUs are basic (no intelligence), while others are intelligent (iPDUs) — they provide metering, outlet-level switching, alerts, etc. (Wikipedia)

What You Can Provide

- Pre-mounting PDUs inside racks or cabinets (e.g. vertical PDUs)

- Intelligent PDUs (metering, remote control, alerts) as an upsell

- Provide redundant PDUs (A/B feeds) or dual-cord circuits

- Provide infrastructure for future PDU expansion (space, conduits)

Design Notes

- Use recessed PDU cavities in cabinets, to not eat into usable U space (Nucor Data Systems)

- Route PDU power feeds via perforated floor or overhead trays, depending on design

- Ensure PDU circuits align with customer power allocation (e.g. 10 kW, 30 kW)

- Implement locking covers or secured cabinets for PDUs if required

- Use busway or modular bus duct if high density

Fiber / Data / Cable Routing

Customers need your cage infrastructure to handle their fiber and networking cabling cleanly. Here’s what you can offer:

- Overhead ladder trays / cable bridges: Provide ladder rack infrastructure above row or over racks to run fiber/backbone cables

- Fiber routing raceways / trunking: Pre-installed pathways from the cage demarc point to rack positions

- Vertical cable managers / troughs: Zero-U vertical racks, side channels

- Fiber panel mounting or splice boxes at demarcation rack

- Pre-terminated fiber drop to a faceplate in each cabinet/rack

- Cable bend radius protection, labeling, routing to avoid interference with airflow

Ladder / Bridge Support Over Racks

If racks are arranged in rows, providing overhead ladder supports (cross-bridges) is helpful:

- Ladder bridges run perpendicular or longitudinally above rack tops

- They allow crossing cables or overhead bundle support

- These should be designed to maintain clearance (~12–18″ above top of rack)

- Ensure structural integrity for anticipated cable weight

- Ground ladder frames to the facility grounding grid

- In some designs, ladder routes connect to vertical risers that go to demarc or cross-connect rooms

Other Infrastructure You Can Provide

- Fire suppression and smoke detectors within cage

- LED lighting overhead / under cabinets

- Leak detection, environmental monitoring (temp, humidity)

- Rack-level sensors (monitoring ambient temp, door open)

- Floor weld plates or anchors for rack securing

- Spare conduits / sleeves for future service expansion

- Cable entry collars or grommets in raised floor

By bundling some or all of these services (or offering them à la carte), you add value, reduce friction for the customer, and differentiate your offering.

Layout & Design Considerations

When defining how many racks / cabinets fit in a cage or how to position them, consider:

Cooling & Airflow

- Hot-aisle / Cold-aisle alignment: Racks should be oriented so cold air comes in front, hot air exhausts to the back. Leave aisle spacing (e.g. 3–4 ft) for access and containment.

- Containment or partial baffles: Overhead or aisle containment (doors, ceiling panels) may be needed.

- Cabinet perforation: Use perforated doors/panels to allow airflow.

- Blanking panels: Cover unused U spaces to prevent recirculation.

- Cable management: Avoid cable blockage of airflow paths.

- Density planning: High power density racks (e.g. 10–20 kW+) may require dedicated cooling or distributed cooling within cage.

Structural & Floor Loading

- Verify the raised floor slab load bearing capacity and rack weight (fully loaded with servers, UPS, PDUs).

- Design anchor points or floor bolt/down plates.

- Consider seismic bracing if in zone requiring it.

- Ensure overhead ladder and tray mounts tie into structural elements above.

Access & Serviceability

- Provide sufficient clearance at front and rear doors for maintenance (door swing clearance).

- Leave aisle widths large enough to roll in equipment (server carts, lifts).

- For private cabinets or compartments, ensure the customer can open doors fully without obstruction.

- Plan walkway access to interior racks.

- In tight cages, consider sliding doors or bi-fold designs to reduce swing swing obstruction.

Cable & Power Routing Efficiency

- Minimize cable length and avoid cross-aisle crossings.

- Design vertical and horizontal pathways such that fiber, copper, and power are separated (for EMI, safety).

- Use color-coded cable trays and segregated zones (power vs data).

- Document pathways and labeling.

Modularity & Expandability

- Leave “growth space” — spare U or rack footprints for future expansion.

- Use modular cabinet systems or compartments that can be reconfigured.

- Provide spare capacity in power/PDUs and conduit pathways.

- Design trunks and ladder trays with slack and capacity for additional cables.

Sample Deployment Scenarios & Layouts

To make this concrete, here are a few hypothetical cage layout scenarios with rack / cabinet options:

Scenario A: Medium-Density Compute in Private Cabinet Rows

- Cage footprint: 10 ft × 20 ft (i.e. 200 ft²)

- You supply three 42U full cabinets in a row, front-to-back orientation with cold aisle in front, hot aisle in back.

- On either side or back wall, you allow one open 4-post rack for networking / patch gear.

- PDUs are pre-mounted in each cabinet, connected to customer power feed.

- Overhead ladder trays run longitudinally above row, with drop cables to each cabinet.

- Fiber demarc is placed at the cage edge, connected via fiber trunk to each cabinet.

Scenario B: Mixed Cabinet + Compartment + Open Rack

- Cage footprint: 12 ft × 25 ft

- One central 2-compartment cabinet (shared shell) but with two compartments, one for compute, one for storage/network.

- Two adjacent 4-post open racks for overflow or low-density gear.

- One half-height cabinet (e.g. 24 RU) for a future project.

- PDUs in each, plus common ladder trays, vertical cable managers.

- Enough spare space for a fourth cabinet later.

Scenario C: High-Density Cluster with Cooling Emphasis

- Cage footprint: 8 ft × 20 ft

- Four open 4-post racks in a tight row (no enclosed cabinets) to maximize cooling — assuming high-density liquid or air cooling arrangements.

- PDUs are floor or overhead fed; overhead ladder trays cross each rack.

- Remote hands support for handling heavy equipment.

- Aisle containment panels at ends to direct airflow, blanking, ducting to return plenum.

In all cases, the customer is choosing among cabinet types and rack configurations; you as operator define what you support, what you supply, and what is optional.

Pricing & Packaging Considerations

While the prior article focused on space/power pricing, here’s a quick tie-in: the type and complexity of rack/cabinet infrastructure should influence pricing tiers or add-ons. For instance:

- Basic open rack — included

- Enclosed cabinet — additional per-cabinet fee

- Multi-compartment or specialized cabinet — premium

- PDU metering / intelligent PDUs — upsell

- Ladder trays, fiber routing, extra raceways — as labeled add-ons

- Field reconfiguration (moving racks, adding partitions) — chargeable

You might bundle rack infrastructure costs into your space/power charges, or itemize them.

How to Present These Options to Customers

When offering the cage + rack/cabinet configurations to customers, it’s good practice to provide template configuration options (e.g. “Starter Kit,” “Dense Compute Pod,” “Network + Storage Hybrid”) so customers don’t have to design from scratch. Each template should show:

- Footprint (sq ft)

- Number and types of racks / cabinets

- Power allocation per rack / cabinet

- Infrastructure included (PDUs, ladder trays, fiber drops)

- Pricing (flat, metered, modular)

Additionally, allow customers to customize: e.g. “Swap an open rack for an enclosed cabinet (adds $Z/month)”; “Add intelligent PDU”; “Provide extra fiber drops”; “Reserve spare U or rack positions for growth.”

Including visual layout diagrams (floor plan, elevation) helps customers understand the real estate and service access implications.

Also, consider offering a “design consultation” service (free or paid) to help customers choose the optimal mix of rack types and densities based on their compute, storage, and power profiles.

Providing flexible rack and cabinet configurations inside cages is a major value differentiator in colocation and data center services.

By supporting open 4-post racks, full cabinets, half cabinets or compartmentalized designs, and bundling in critical infrastructure (PDUs, fiber routing, ladder trays), you cater to a wider range of workloads and customer preferences.

The keys to success are:

- A modular, scalable approach

- Thoughtful layout and cooling planning

- Infrastructure forward (power, cable, ladder, grounding)

- Clear customer-facing templates with optional upgrades